Are you looking for an answer to the topic “What is an annealing oven used for?“? We answer all your questions at the website Ecurrencythailand.com in category: +15 Marketing Blog Post Ideas And Topics For You. You will find the answer right below.

Annealing is a heat treatment process for glass and soft metals that reduces hardness, increases ductility and helps eliminate internal stresses. An annealing oven—also called an annealing furnace—heats materials to a specified temperature and then cools it at a very slow rate.The process of annealing glass relieves internal stresses, which could otherwise leave it susceptible to cracking or shattering in response to minor mechanical or thermal shock. This makes annealing a vital step in the production of strong, stable, and heat-resistant glass.To perform an annealing process, a material that can be altered by heat treatment must be used. Examples include many types of steel and cast iron. Some types of aluminum, copper, brass and other materials may also respond to an annealing process.

Why is an annealing oven necessary in glass making?

The process of annealing glass relieves internal stresses, which could otherwise leave it susceptible to cracking or shattering in response to minor mechanical or thermal shock. This makes annealing a vital step in the production of strong, stable, and heat-resistant glass.

What is used for annealing?

To perform an annealing process, a material that can be altered by heat treatment must be used. Examples include many types of steel and cast iron. Some types of aluminum, copper, brass and other materials may also respond to an annealing process.

Mobile Glassblowing Studios Annealing Oven Overview

Images related to the topicMobile Glassblowing Studios Annealing Oven Overview

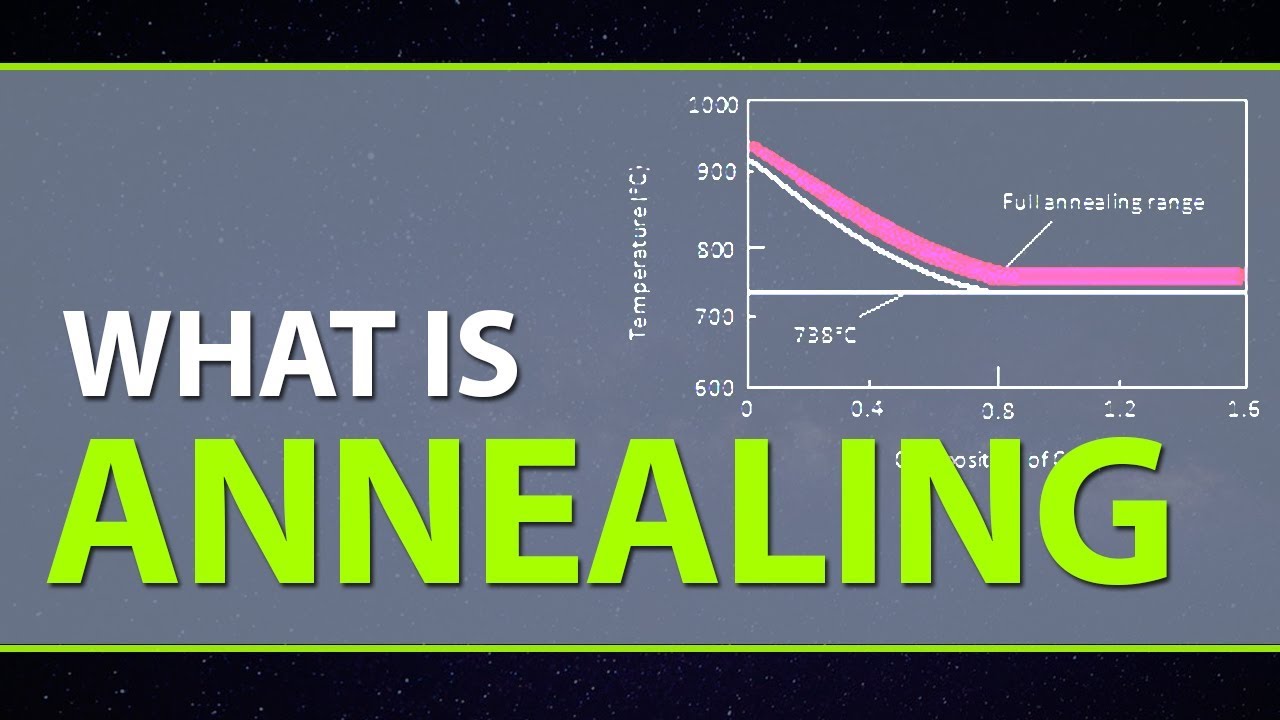

What is the purpose of annealing and its temperature range?

The full annealing process consists of heating to the proper temperature and then cooling slowly, through the transformation range, in the furnace. The purpose of annealing is to produce a refined grain, to induce softness, improve electrical and magnetic properties, and sometimes to improve machinability.

Why is annealing important?

To relieve stresses, which can lead to breakage at room temperature, it is necessary to cool glass in a controlled manner through a predetermined temperature gradient. This allows the surface and interior to cool uniformly. This controlled process for cooling glass to relieve interior stresses is called “annealing.”

What happens if you dont anneal glass?

Glass that has not been properly annealed retains thermal stresses caused by quenching, which indefinitely decrease the strength and reliability of the product. Inadequately annealed glass is likely to crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress.

Can I use an oven to anneal glass?

Glass annealing ovens or furnaces are used by glassblowers to eliminate stresses created in glassware during the glassblowing process. Under controlled conditions, the oven slowly and evenly heats the glass to annealing temperature.

What products are annealed?

Most commonly, many types of steel and cast iron are annealed in the manufacturing industry. There are also specific types of aluminum, copper, and brass that can be annealed. While steel is generally cooled to room temperature in still air, copper and brass can also be quenched in water.

See some more details on the topic What is an annealing oven used for? here:

Annealing Oven & Furnace | Industrial Ovens – International …

The function of an Annealing Oven is to perform the process of softening an object or changing other properties of the object through cycles of heating and …

Glass Annealing Oven

Glass annealing ovens or furnaces are used by glassblowers to eliminate stresses created in glassware during the glassblowing process.

Standard Annealing Ovens – Thermal Product Solutions

Annealing ovens are most commonly used for metal, plastic and glass. To prevent stresses and cracking of plastic or metal parts during the machining process …

industrial annealing ovens and furnaces

A specialized annealing oven gives users the ability to tightly control and monitor the heating and cooling process, allowing for proper recrystallization to …

Is annealing the same as tempering?

Both heat treatments are used for treating steel, although annealing creates a softer steel that is easier to work while tempering produces a less brittle version that is widely used in building and industrial applications.

Why do you anneal metal?

The Benefits of Annealing

Annealing steel or any other metal involves heating it to a specific temperature and allowing it to cool at a specified rate. Doing so removes impurities in the grain, increasing the metal’s ductility and reducing its hardness.

Why do you anneal after cold working?

Annealing also restores ductility. During cold working, the metal can become hardened to the extent that any more work will result in cracking. By annealing the metal beforehand, cold working can take place without any risk of cracking, as annealing releases mechanical stresses produced during machining or grinding.

What are the 3 stages of annealing?

- Recovery stage.

- Recrystallization stage.

- Grain growth stage.

What is the ideal temperature for annealing to take place?

The temperature range for process annealing ranges from 260 °C (500 °F) to 760 °C (1400 °F), depending on the alloy in question. This process is mainly suited for low-carbon steel. The material is heated up to a temperature just below the lower critical temperature of steel.

What is Annealing | Types of Annealing Process | Purpose Advantages of Annealing

Images related to the topicWhat is Annealing | Types of Annealing Process | Purpose Advantages of Annealing

What are the disadvantages of annealing?

It has to be convert into pearlite and ferrite. As a result of the process, you will get the material that is more ductile. The downside of the full annealing is that we get the material of smaller tensile strength as an output of this process.

What does annealing do to stainless steel?

Austenitic stainless steels cannot harden via heat treatment. Instead, these steels work harden (they attain hardness during their manufacture and formation). Annealing these stainless steels softens them, adds ductility and imparts improved corrosion resistance.

What does annealing do to aluminum?

The Purpose of Aluminum Heat Treating and Annealing

Annealing is done to soften the material, reduce stress, and to give it increased workability. This is often needed because aluminum alloys are subject to work hardening, or strain hardening.

How long does glass stay in an annealer?

Annealing is the gradual cooling of the glass down to room temperature. Our annealing furnaces run on a computer program and the length of time for pieces the size we tend to make is about 16 hours. Larger pieces take a longer period of time in the annealer.

Why is annealed glass used?

The most common and economical choice of glass is annealed glass. Due to its clear and smooth surface, it is often used for applications that require optical clarity. Annealed glass can transmit 87% of the light incident on it. This makes it an excellent choice for glazing solutions.

Where is annealed glass used?

Annealed glass is often used in items such as tabletops, cabinet doors, and basement windows. Its tempered counterpart is typically found in balcony doors, athletic facilities, swimming pools, facades, shower doors and bathroom areas, exhibition spaces and displays, and computer towers and cases.

Can you anneal glass without a kiln?

Technically you do not use a kiln to cool glass, you use it to anneal glass. In other words you use kiln to heat glass to the “strain point” where glass molecules can slide around inside glass pieces and the internal stresses are relieved.

Can you anneal glass in a kiln?

Annealing is one of the steps of firing glass. Kilns are programmed to slowly cool (anneal) glass to eliminate any stress after it is formed. Glass pieces may crack or shatter when subject to small temperature change or mechanical shock and annealing glass is critical to its durability.

Can you use an oven as a glass kiln?

Not only can microwave ovens fuse glass, but most ovens can do it in less than 10 minutes. A pendant made in a microwave kiln. Blue glass sprinkled with dichroic glass.

What annealed mean?

1 : to heat and then cool (as steel or glass) usually for softening and making less brittle. 2 : to heat and then cool (double-stranded nucleic acid) in order to separate strands and induce combination at lower temperatures especially with complementary strands. intransitive verb.

ANNEALING FURNACE

Images related to the topicANNEALING FURNACE

How can I anneal steel at home?

So how do you anneal steel? To anneal steel, heat it up about 100 degrees F above its critical temperature, soak it at that temp for 1 hour per inch of thickness, and let it cool at a maximum rate of 70 F per hour. Ok, that’s the short answer.

What are the uses of annealed metals?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

Related searches to What is an annealing oven used for?

- glass annealing oven for sale

- annealing oven synonym

- annealing oven crossword

- small annealing oven

- plastic annealing oven

- annealing oven for metal

- what is an annealing oven

- annealing oven glass

- diy annealing oven

Information related to the topic What is an annealing oven used for?

Here are the search results of the thread What is an annealing oven used for? from Bing. You can read more if you want.

You have just come across an article on the topic What is an annealing oven used for?. If you found this article useful, please share it. Thank you very much.