Are you looking for an answer to the topic “What’s the difference between MIG and MAG welding?“? We answer all your questions at the website Ecurrencythailand.com in category: +15 Marketing Blog Post Ideas And Topics For You. You will find the answer right below.

MIG welding uses inert or inactive gases for example argon and helium for shielding the weld while MAG welding uses active gases such as CO2. MIG welding is mainly used for non-ferrous metals like copper, aluminum, copper alloys, and titanium, etc.Shielding gas cylinder for MAG welding is comparatively cheaper. MIG welding is preferred for joining non-ferrous metals (like aluminum). MAG welding is preferred for joining ferrous metals (like mild steel or stainless steel).The only difference between MIG and MAG is the type of shielding gas used. The make-up of the shielding gas is important as it has a significant effect on the stability of the arc, metal transfer, weld profile, penetration, and the degree of spatter.

Table of Contents

Which is better MIG or MAG welding?

Shielding gas cylinder for MAG welding is comparatively cheaper. MIG welding is preferred for joining non-ferrous metals (like aluminum). MAG welding is preferred for joining ferrous metals (like mild steel or stainless steel).

Is MAG welding the same as MIG?

The only difference between MIG and MAG is the type of shielding gas used. The make-up of the shielding gas is important as it has a significant effect on the stability of the arc, metal transfer, weld profile, penetration, and the degree of spatter.

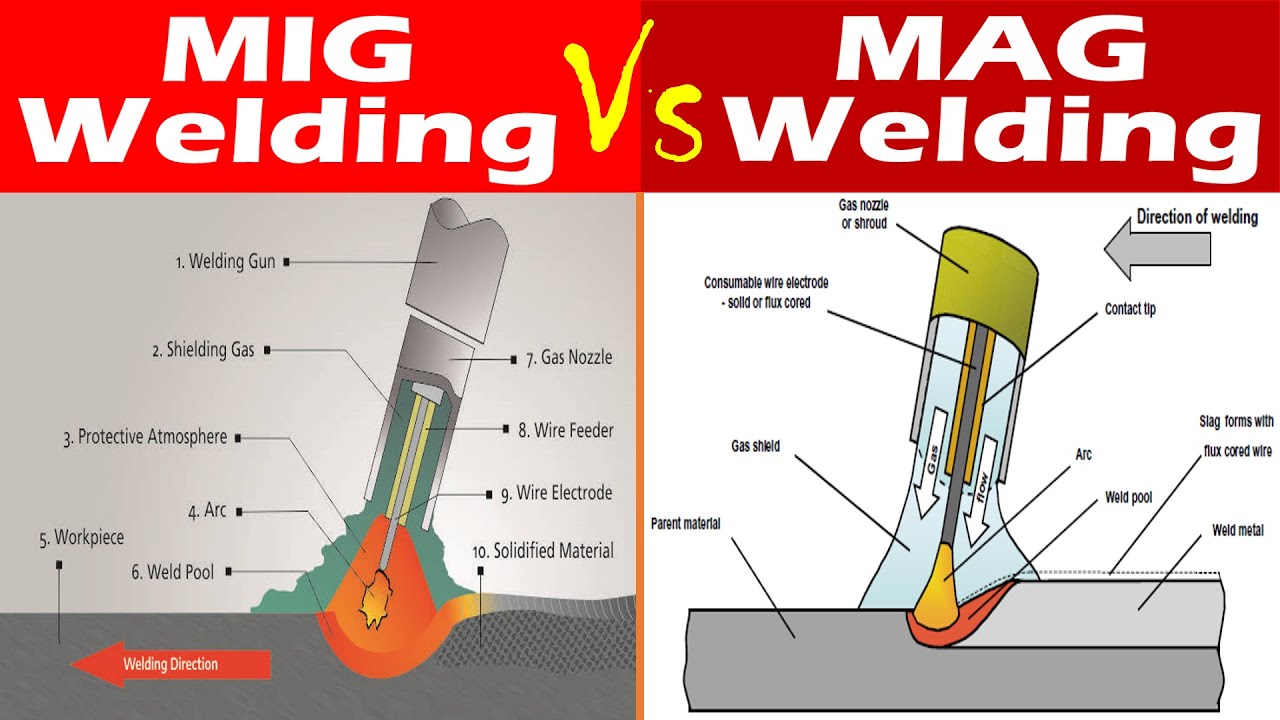

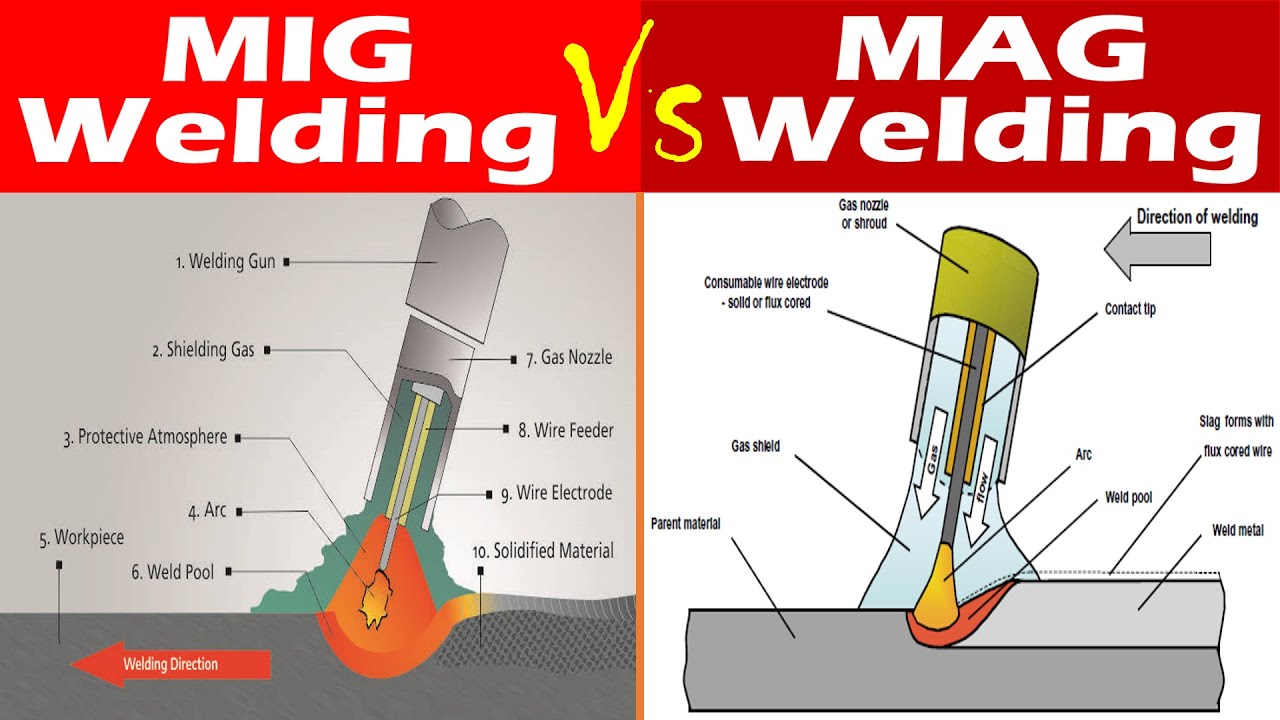

Differences between MIG Welding and MAG Welding.

Images related to the topicDifferences between MIG Welding and MAG Welding.

What is a MAG welder used for?

MAG welding is a method of arc welding in a shielded environment, for which carbon dioxide (CO2) and an uncoated electrode are used. MAG welding is used for: low-alloyed construction steels; thin and medium-thick sheet metal.

Can you mag weld with a MIG welder?

MIG/MAG processes can be used with components of different thicknesses and geometries, and which are made from different materials. MIG welding is particularly suited to the non-ferrous metals aluminum, magnesium, copper, and titanium. MAG welding is usually used to weld unalloyed, low-alloy, and high-alloy steels.

What are the disadvantages of MIG welding?

- Higher initial setup cost.

- Atmosphere surrounding the welding process has to be stable (hence the shielding gasses), therefore this process is limited to draught free conditions.

- Higher maintenance costs due to extra electronic components.

What does MIG stands for?

| Acronym | Definition |

|---|---|

| MiG | Metal Inert Gas (welding) |

| MiG | Made in Germany (gaming clan) |

| MiG | Marfin Investment Group (est. 1998) |

| MiG | My Image Gallery (photo album/management software) |

What are some advantages to MIG welding?

- MIG welding is fast. With any welding, the time taken has to reflect the difficulty of the join and the quality desired from the finished weld. …

- Ease of use. …

- MIG weld quality. …

- Long-pass welding. …

- Penetration matters. …

- Fewer stops and starts. …

- Electrode stub loss? …

- MIG works with many metals or alloys.

See some more details on the topic What’s the difference between MIG and MAG welding? here:

Difference Between MIG and MAG Welding

Differences between MIG and MAG welding ; Shielding gas does not induce any chemical element into the weld bead. As the active shielding gas …

What is MIG/MAG Welding? The Basics and advantages

MIG/MAG welding is actually two different welding processes: MIG welding stands for metal inert gas welding. This process uses inert – i.e., non …

Q: What Is the Difference Between MIG and MAG Welding

The difference between MIG and MAG welding is the type of gases used in the welding process. MIG stands for metal inert gas, so MIG welding only uses inactive …

MIG Welding vs. MAG Welding: The Differences

MIG welding and MAG welding differ in the gases used to shield them. MIG welding uses inert gases and MAG welding uses active gas mixtures. MIG welding is used …

What gas do you use for MIG?

The most common of the reactive gases used in MIG welding is Carbon Dioxide (CO2). It is the only one that can be used in its pure form without the addition of an inert gas. CO2 is also the least expensive of the common shielding gases, making it an attractive choice when material costs are the main priority.

What does TIG mean in welding?

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW) is an arc welding process that produces the weld with a non-consumable tungsten electrode.

What type of welding is strongest?

TIG welding is often considered the strongest weld since it produces extreme heat, and the slow cooling rate results in high tensile strength and ductility. MIG is also an excellent candidate for the strongest type of weld because it can create a strong joint.

4 Types of Welding Explained: MIG vs TIG vs Stick vs Flux Core

Images related to the topic4 Types of Welding Explained: MIG vs TIG vs Stick vs Flux Core

Is arc welding stronger than MIG?

Some argue that stick welding is stronger than MIG welding, since it offers better penetration for thicker materials. However, MIG welding can provide good welds despite not being as effective on thicker metals, and is better for joining thinner metals with a good finish and less risk of burn-through.

What does MIG and TIG stand for?

Types of arc welding include metal inert gas (MIG) welding and tungsten inert gas (TIG) welding, among others.

Why is it called MIG welding?

A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas. The technical name for it is gas metal arc welding (or GMAW), and the slang name for it is wire welding.

Why active gas is used in MAG welding?

MAG welding uses an active gas that makes it react well with construction steels and thick to medium-thick sheet metal. MAG welding produces intense heat, which can cause the CO 2 to split into carbon monoxide and oxygen.

Which is the easiest welder to use?

MIG welding is generally the easiest type of welding for a beginner to learn. MIG welders use a feed wire that runs through the machine at a preselected speed. This makes the process relatively fast and produces consistent welds.

Is TIG better than MIG?

Precision: TIG welds are more precise and have a higher general quality than MIG welds. Cleaner process: The TIG process is cleaner and better for the environment. No need for filler: TIG welding doesn’t require filler material. Greater control: The pedal used allows for foot control to adjust heat input.

Do gasless MIG welders work?

Can any Mig be used for Gas AND Gasless Welding? No, a Mig Welder will be designed to either use Wire with Gas, Self Shielding (gasless) Wire, or both (Gas/No Gas). The difference lies in the Polarity of the Torch.

What MiG was in Top Gun?

The aircraft used for the fictional MiG-28s are Northrop F-5E (single seat) and F (two seat) Tiger IIs, which were used by TOP GUN as aggressor aircraft.

Can you mig weld inside?

MIG (Metal Inert Gas) Welding is a welding process that uses a gas shield to weld metal. The gas keeps the metal being welded from being affected by natural elements such as oxygen. This method allows for more continuous operation. Note: MIG welding only can be done indoors.)

MIG and MAG welding difference||#GMAW Kya hai

Images related to the topicMIG and MAG welding difference||#GMAW Kya hai

What is better for welding aluminum TIG or MIG?

Generally, two processes are used for aluminum welding: GTAW (TIG) and GMAW (MIG). Most welders in the business will say TIG is the better option for welding aluminum because it allows for better results on lighter gauge materials. When done correctly, TIG welding aluminum can produce quality welds.

What current do you use to weld aluminum?

Use Appropriate Amperage

The rule of thumb for aluminum GTAW is to use 1 amp for every thousandth (0.001) of material thickness. In other words, welding a base material that is 1⁄8 in. (0.125) thick would require about 125 amps.

Related searches to What’s the difference between MIG and MAG welding?

- what is mag welding used for

- mig welding

- mag welding full form

- difference between mig and tig welding

- mag welding gas

- mag welding process

- difference in mig and mag welding

- what is mig and mag welding

- advantages of mag welding

- mig vs mag vs tig

- what’s the difference between mig and mag welding

Information related to the topic What’s the difference between MIG and MAG welding?

Here are the search results of the thread What’s the difference between MIG and MAG welding? from Bing. You can read more if you want.

You have just come across an article on the topic What’s the difference between MIG and MAG welding?. If you found this article useful, please share it. Thank you very much.